Description

- High durability against contact with workpieces or wire brushes (sensor head/housing: stainless steel)

- Reduced risk of malfunction caused by aluminum chips

- 2-color LED indicator for easy status monitoring

- Malfunction identification and predictive maintenance with real-time monitoring (IO-Link models : PRFDCM□-□-IL2)

- Oil resistant cable

- Protection Rating

– Cable type, cable connector type: IP66, IP67 (IEC standard)

– Connector type : IP66, IP67 (IEC standard), IP67G (JEM standard), IP68 - PTFE coating prevents malfunctions caused by welding spatter (spatter-resistant PRFDA□ models)

|

|

|

|

|

|

|

|

|

|

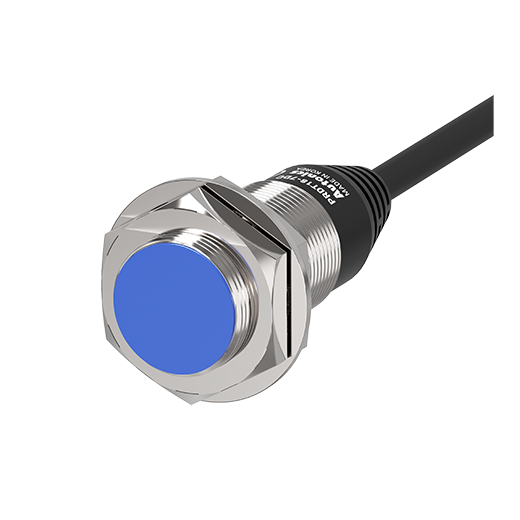

Available in Various Sizes and Cable Types

The sensors are available in M8, M12, M18, M30 size models, and cable/cable connector/connector types allowing installation in tight or limited spaces and various other user settings

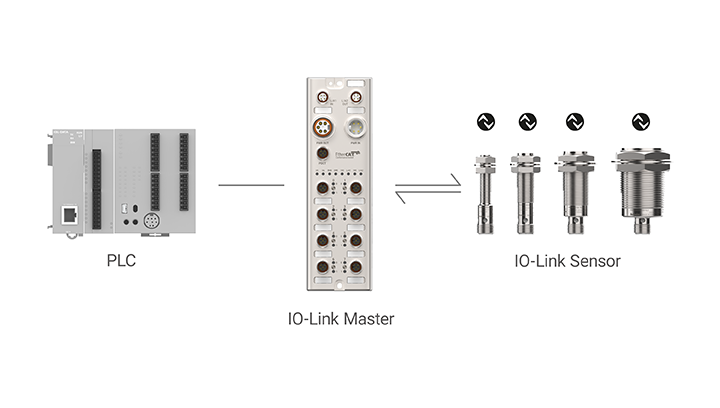

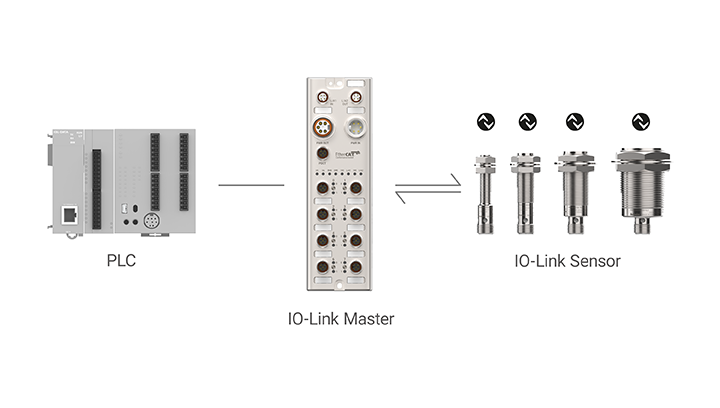

Easy Maintenance with IO-Link Communication (IO-Link Model only)

IO-Link communication models feature detection of abnormalities in sensors such as over-access, unstable, disconnection detections for convenient maintenance. IO-Link Master is required for IO-Link communication and IODD file can be download from our website.

Full-Metal Sensor Heads Provide High Durability

The stainless steel 303 sensor heads provide high durability, making the sensors ideal in environments where the sensor heads can be worn due to workpieces or wire brushes.

*Except for ø8mm model.

|

|

|

Sensors can be used safely even with the wear on the sensor heads caused by continuous wire brush use.

Reduced Risk of Malfunction Caused by Aluminum Chips

The sensors are designed to minimize the risk of malfunction due to aluminum chips, offering high performance in environment with metal debris.

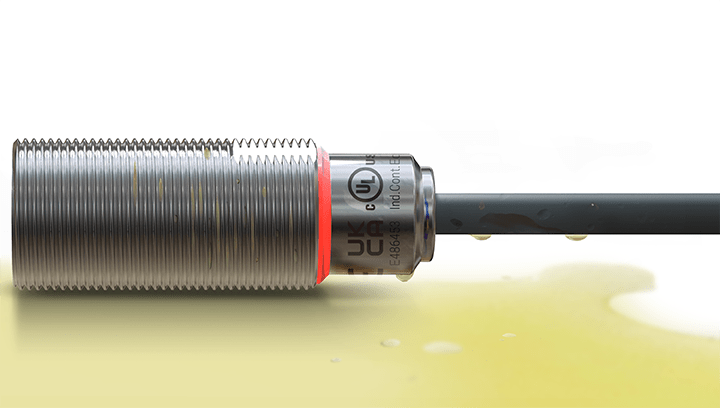

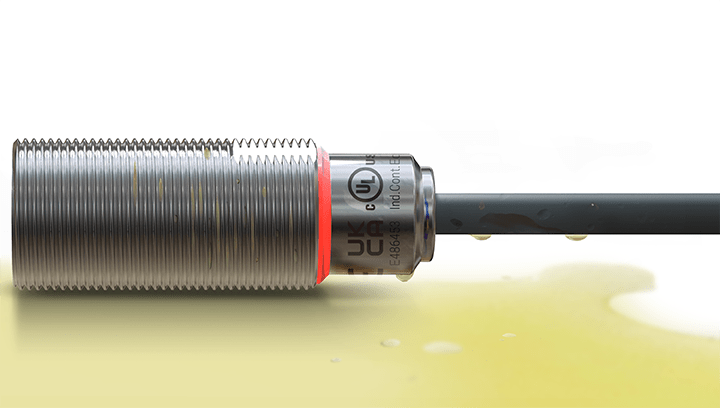

Oil-Resistant (PVC) Cable

The robust oil-resistant cable allows the sensors to be installed in environments with hydraulic fluids or cutting fluids.

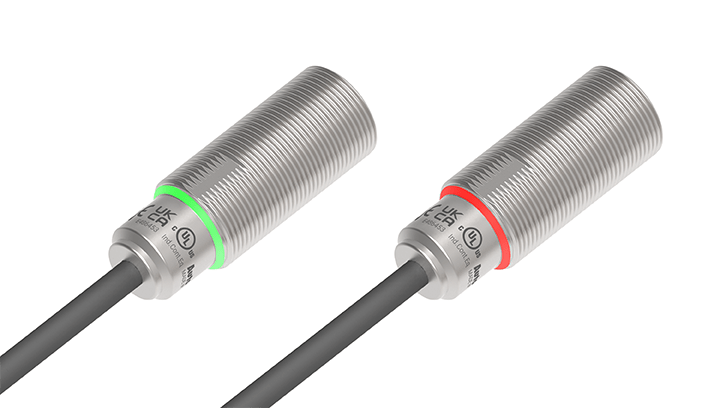

Status Indicator for Quick Identification

Operation indicator and stability indicators allow users to quickly identify operation status from various angles. IO-Link communication models provide communication status.

*Green LED : Stability, Communication / Orange or Red LED : Operation / Green, Orange LED : Malfunction

*Ring Type : Cable, Cable Connector Type

*4 Direction LED : Connector Type

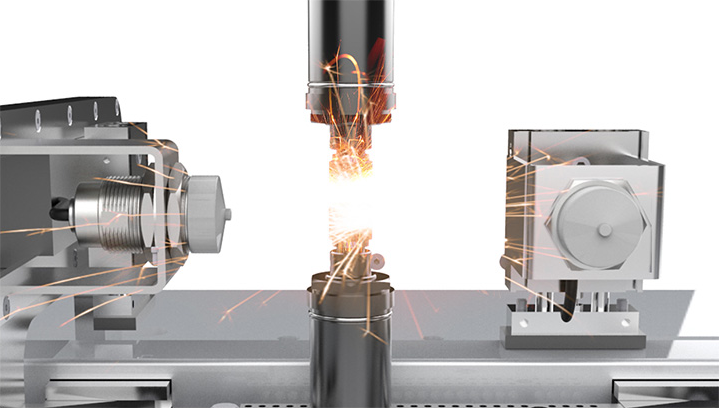

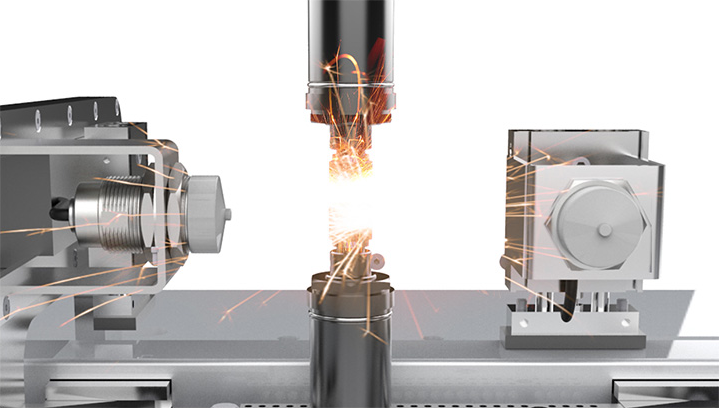

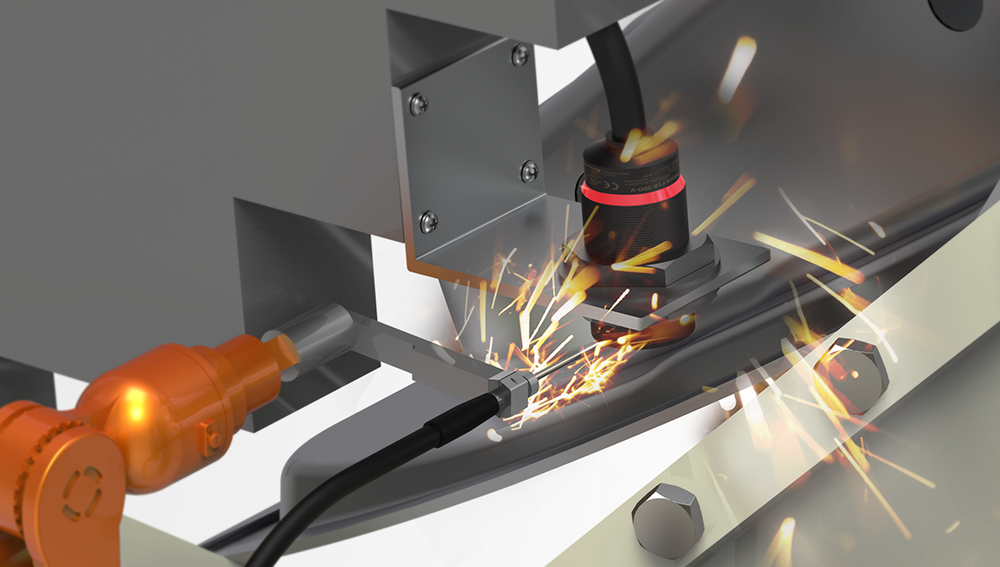

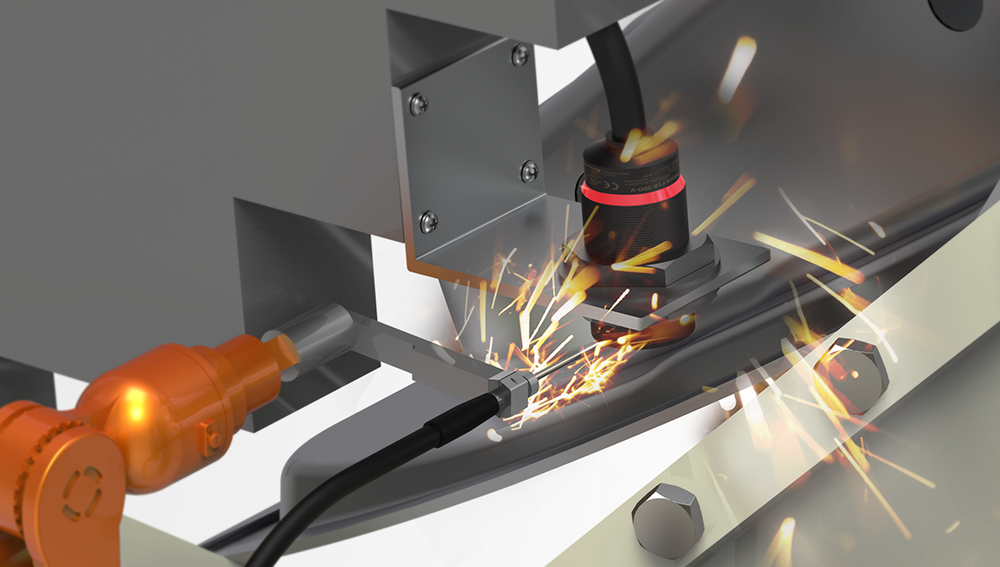

High Durability in Welding Environment

Full-metal inductive sensors feature high resistance to magnetic field noise from welding current and the non-stick PTFE coating prevents welding spatter from sticking on to the sensors which minimizes the risk of malfunctions during welding applications.

*Spatter-Resistant PRFDA□ Models

Normal operation even in at 10 mm front installation and 50 mm side installation. (M18 models)

*Minimum distance may change depending on welding environment

*Protection cover sold separately

*PTFE (Polytetrafluoroethylene) Coating : A synthetic fluoropolymer of tetrafluoroethylene which has high heat resistance properties, low coefficient of friction, high abrasion resistance, non-stick properties, and excellent dielectric properties.

Protection Rating

The IP66, IP67, IP68 protection rating allows stable and error-free operation even in wet or dusty environments

Applications

-

Automated Automotive Manufacturing Process

Automated Automotive Manufacturing Process – Stamping process / Welding process / Painting process

-

Meat Processing Conveyors

Full-metal inductive proximity sensors used to detect the location of food trays in meat processing lines.