Description

- Stable glass substrate detection with using double scan method

- Sensing distance: glass G size +30%

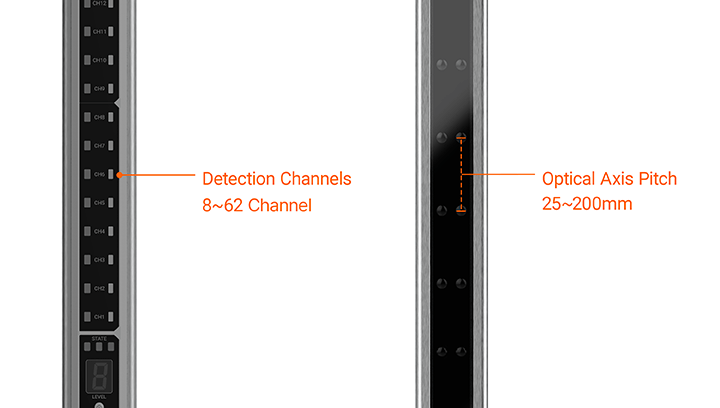

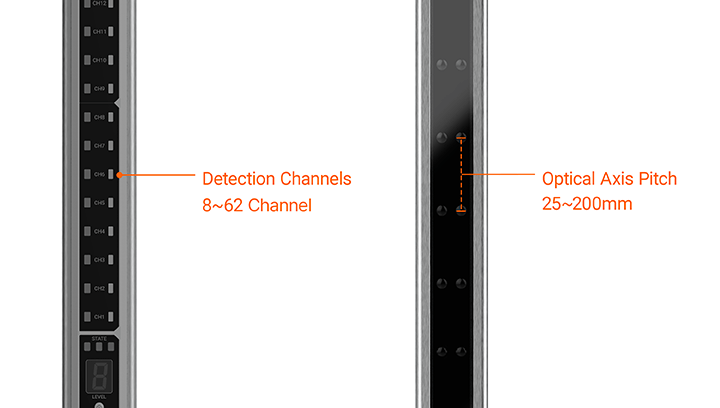

- Customized models available: sensing channels (8 to 62 channels), optical axis pitch (25 to 200 mm)

- Communication output: CC-Link (ver 1.1, 2.0), EtherCAT

- Easy installation with installation instruction mode

- Mutual interference prevention, bent optical axis alarm, 9-stage sensing level setting, emitter error alarm

- Bright status indicators on slave units

|

|

|

|

|

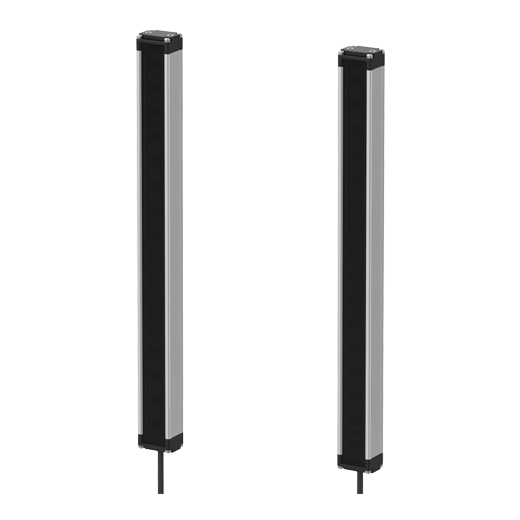

Customized Models Available

The sensors allow different sensing channels, optical axis pitches and sensing area depending on diverse user environments.

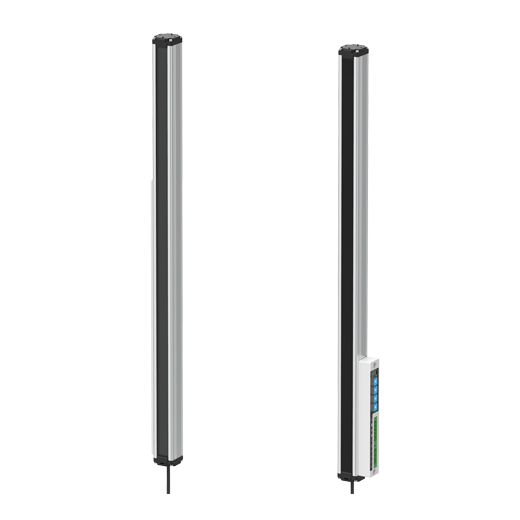

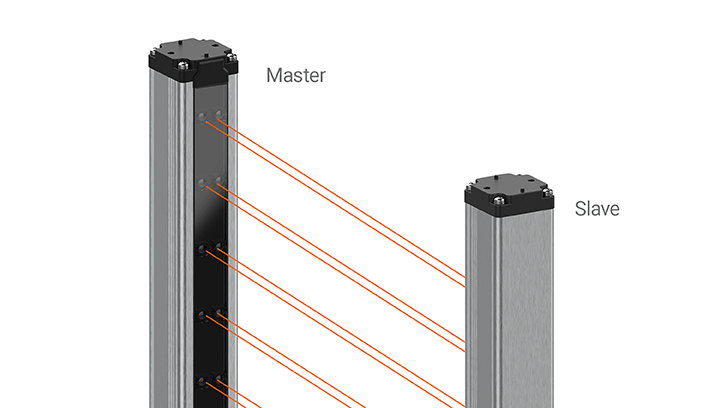

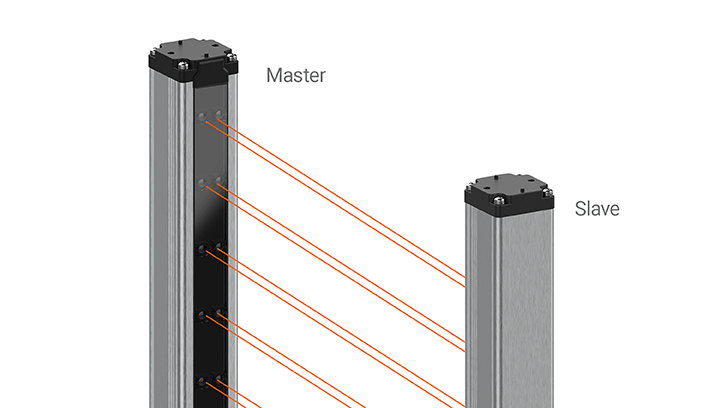

Double Scan Method for Stable Glass Substrate Detection

The master and slave units contain both emitter and receivers which allow detection of light amount from both sides, offering high optical detection performance. This double scan method allows detection of ultra-thin glass substrates with low levels of light reflection.

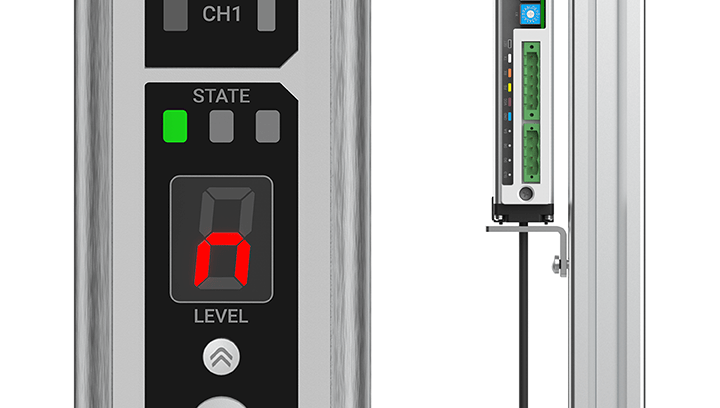

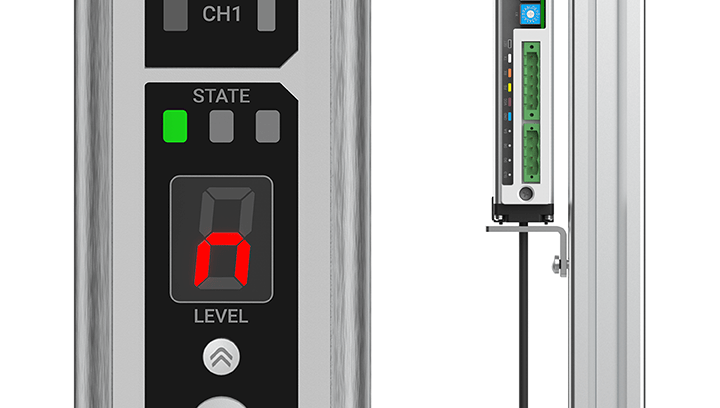

Diverse Modes Allowing Easy Installation

Users can install the sensors easily with installation instruction mode.

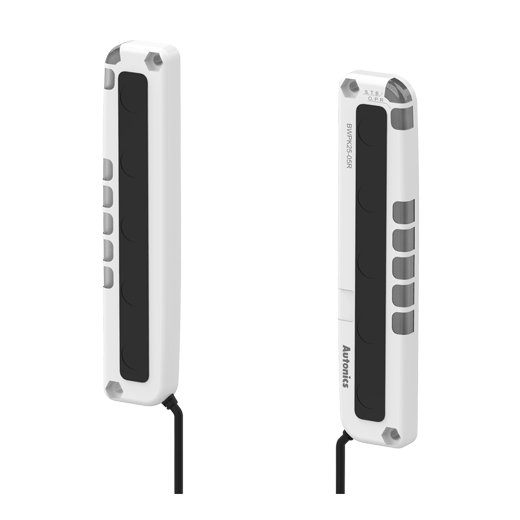

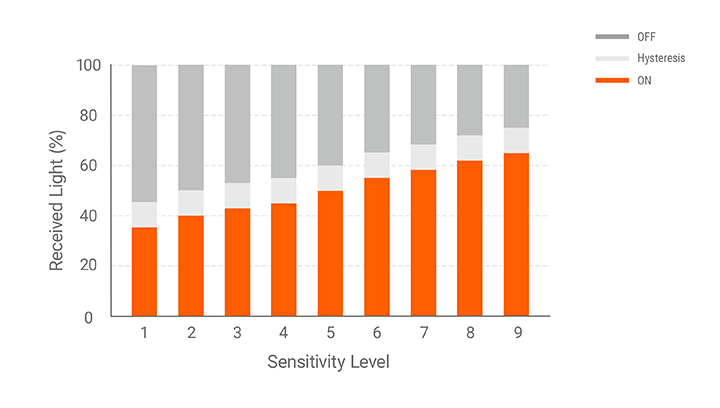

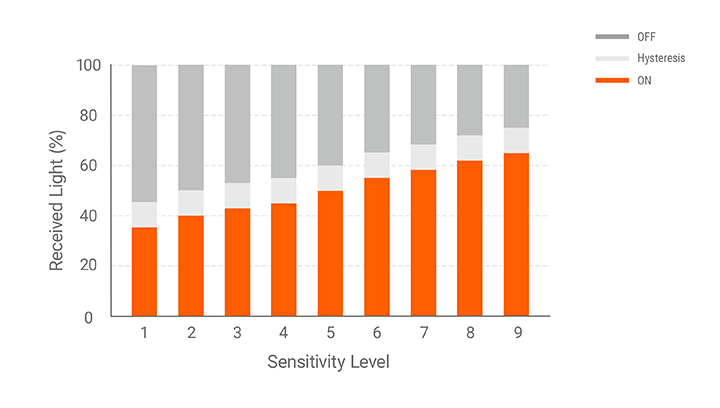

Minimize Influence from Diffuse Reflection with 9 Different Sensitivity Levels

Users can set different sensing levels by channels to minimize influence of bent glass or defused reflection. The sensing level can be set in 9 different sensitivity levels.

CC-Link, EtherCAT Communication Protocol Support

The units offer support for CC-Link or EtherCAT communication support and also offer options for connector type connection and terminal type connection.

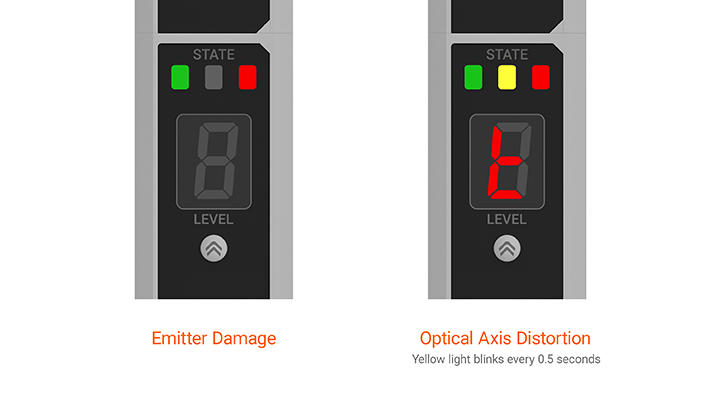

Various Alarms

The sensors allow stable operation with various alarms such as optical axis distortion and emitter damage.

Mutual Interference Prevention Function

When 2 or more units need to be installed near each other, users can set different frequency for each unit to prevent malfunction from mutual interference.