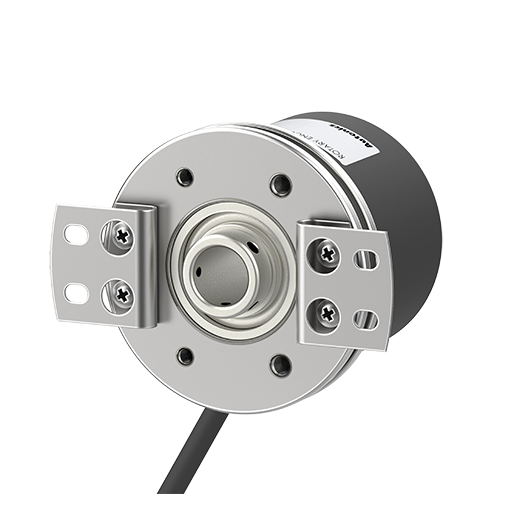

Description

- High accuracy in harsh environments including shock, vibration, dust, and humidity (compared to optical encoders)

- Longer service life compared to optical encoders

- Output code : binary

- Output interface options : Parallel, SSI (Synchronous Serial Interface)

- 23-bit (8,388,608) total resolution

- – 10-bit single-turn (1024 divisions)

- – 13-bit multi-turn (8192 revolutions)

- Power supply : 12-24VDC ±5%

- Overflow alarm (OVF) function

- IP50 protection structure (IEC standard)

|

|

|

|

|

Working Principle of magnetic Encoders

- High Precision Even in Demanding Conditions : Unlike optical encoders which require perfect gaps between the disc and the optical sensor, magnetic encoders work by generating a signal as the magnetic field rotates. This allows higher tolerance for the encoders, allowing precise and accurate measurements in environments with shock, vibration, dust or humidity.

- Longer Service Life (Compared to Optical Encoders) : magnetic rotary encoders do not contain sensitive components like optical encoders, allowing them to last longer in challenging environments. With higher shock and vibration resistance, and less chance of dust or condensation build-up, magnetic encoders inherently have a longer life cycle than its optical counterparts.

Cost-Efficient Sensor Chip Developed by Autonics

The magnetic sensor chip is self-developed by Autonics, allowing the encoders to be offered at relatively low prices compared to other brands.

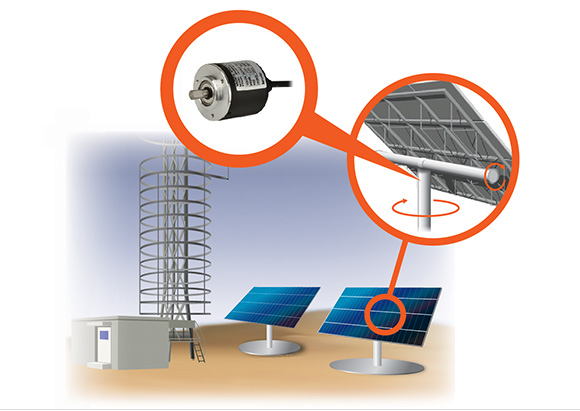

Applications

magnetic absolute encoders used to control the rotation angle of solar panels in relation to position of the sun.