Description

- Multi-channel (4-channel : TM4/2-channel : TM2) input and output control

- Module connection and expansion with expansion connectors

– Communication between modules

– No additional power supply wiring

– Expandable up to 31 units (124-channels/62-channels) - High-speed sampling cycle (4-channel : 100ms/2-channel : 50ms)

- Simultaneous heating and cooling control function

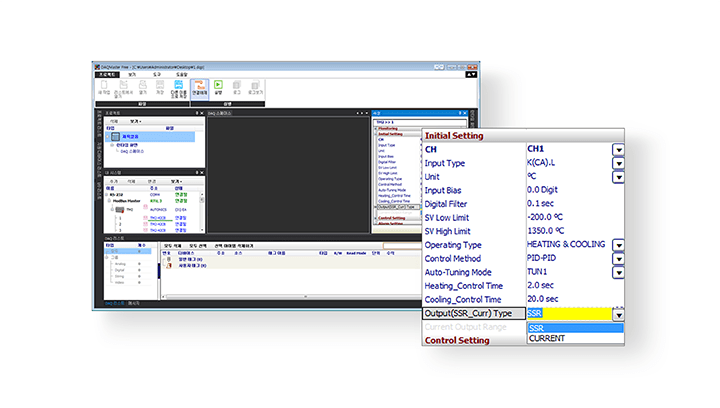

- Parameter configuration via PC (USB and RS485 communication)

– DAQMaster software included (comprehensive device management software)

– Parameter configuration without power supply or wiring using SCM-US

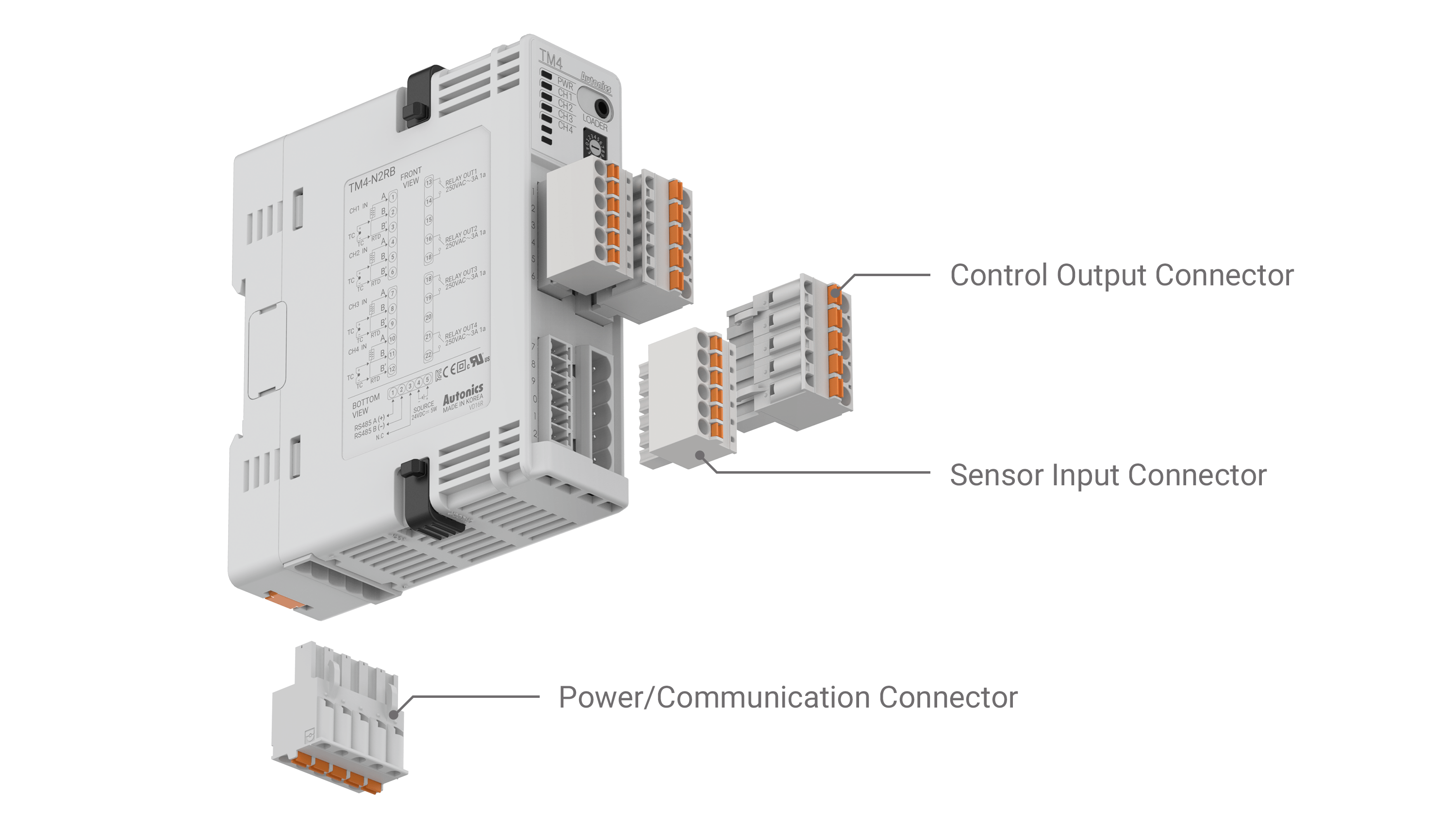

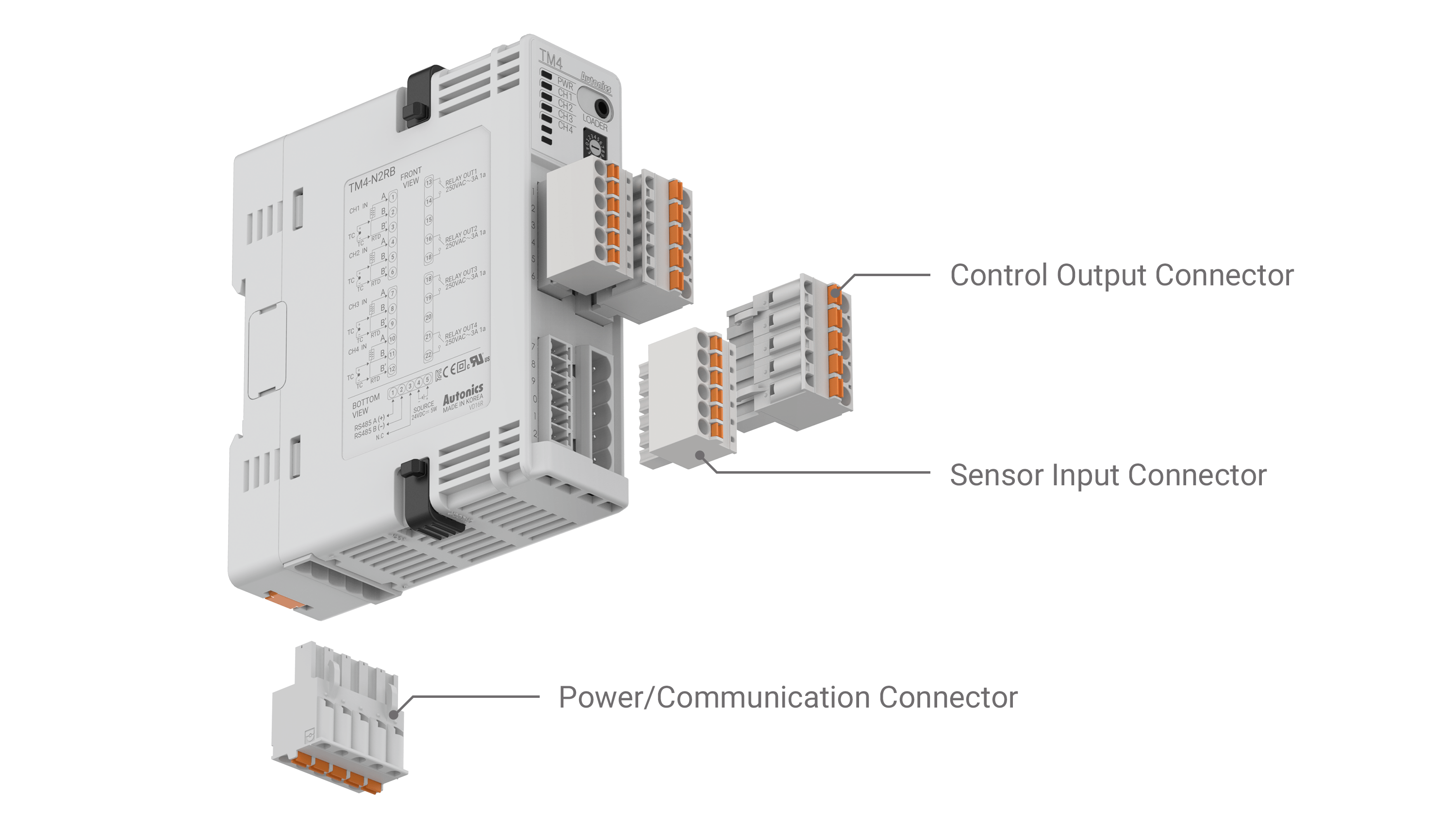

Communication converter sold separately : SCM-WF48 (Wi-Fi to RS485 USB converter), SCM-US48I (USB to RS485 converter), SCM-38I (RS232C to RS485 converter), SCM-US (USB to serial converter) - Easy wiring and maintenance with various connectors : sensor input connector, control output connector, power/communication connector

- RS485 Communication

– Protocol : Modbus RTU or ASCII

– Communication speed : Max. 115,200bps - Screwless push-in type connection for simple and easy connection

- Isolated input channels (dielectric strength : 1000VAC)

- Heater disconnect alarm function (CT input)

Current transformer (CT) sold separately : CSTC-E80LN, CSTC-E200LN, CSTS-E80PP

|

|

|

|

|

|

|

|

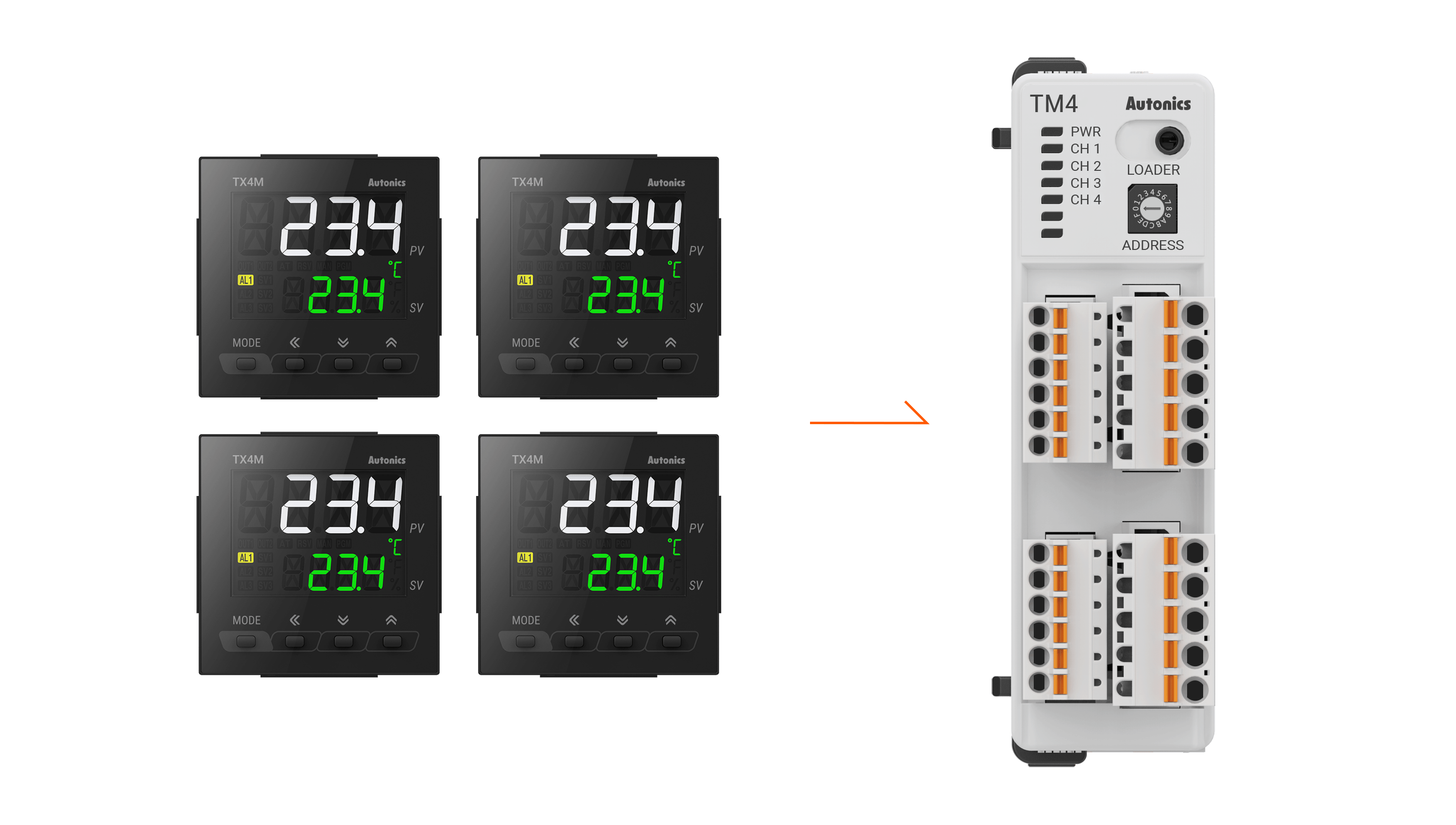

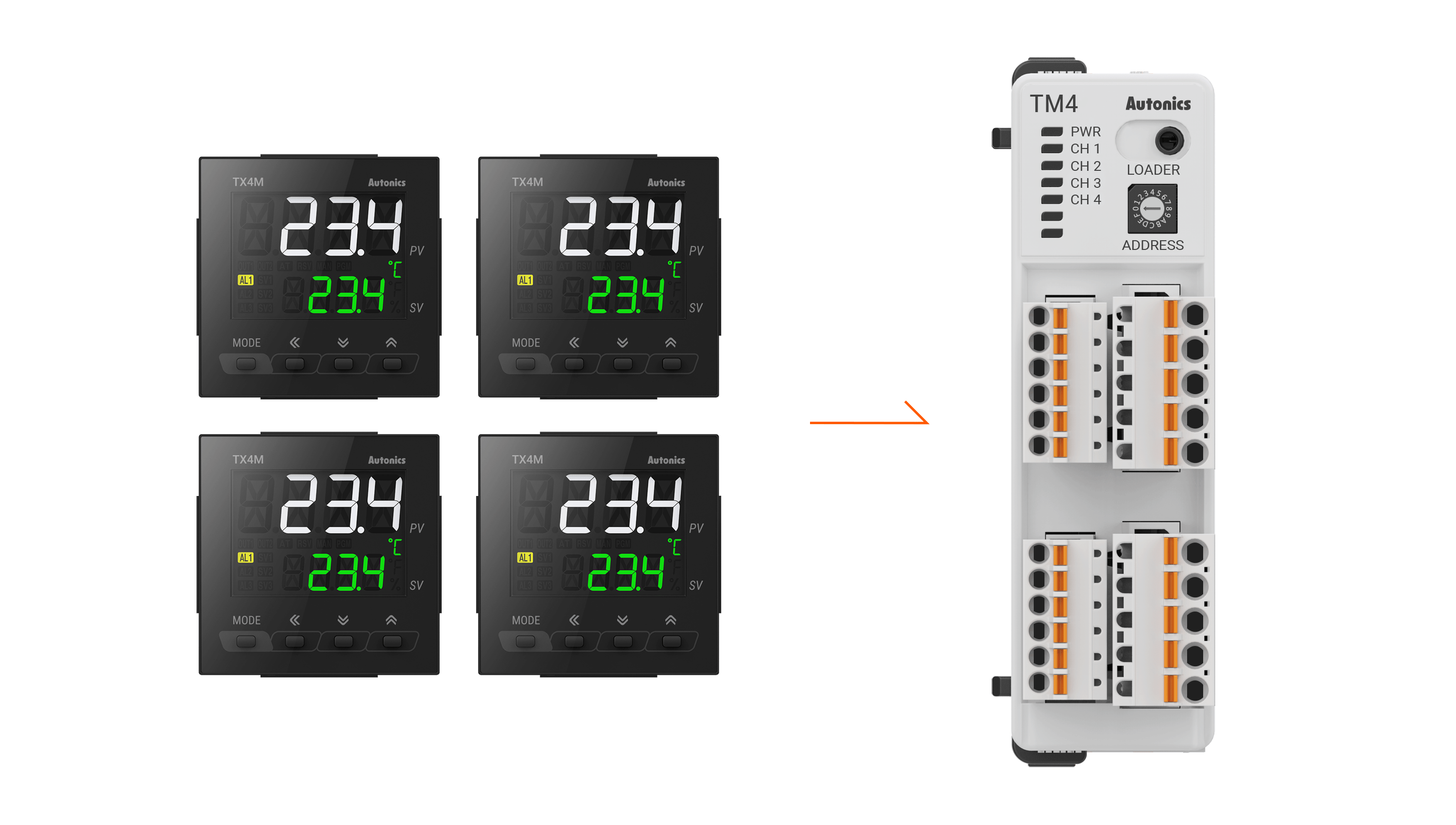

Multi-Channel Input and Output Control (2-Channels/4-Channels)

The TM series temperature controllers are capable of controlling 2-channels or 4-channels of input and outputs, capable of performing as 4 separate temperature controllers

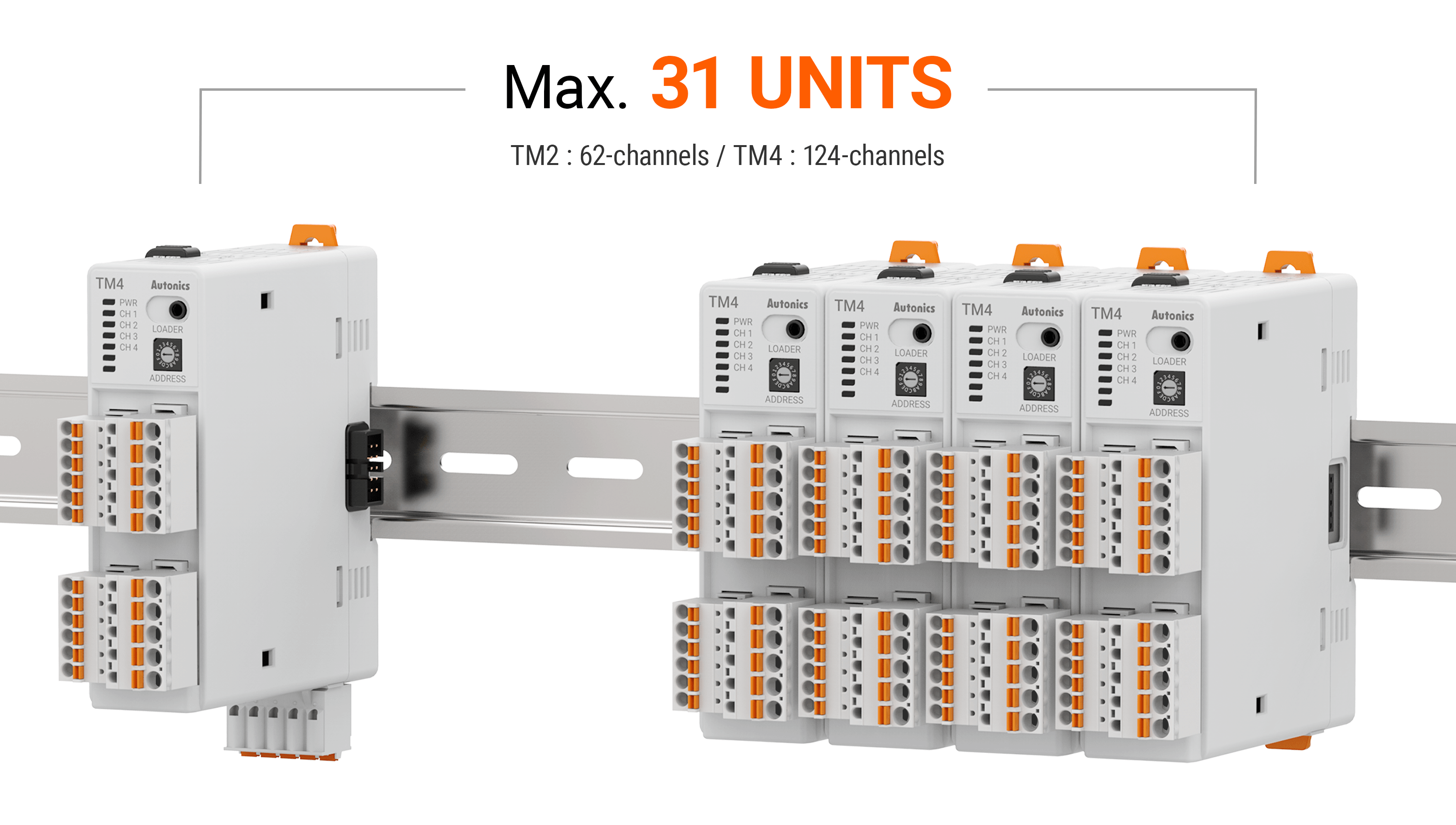

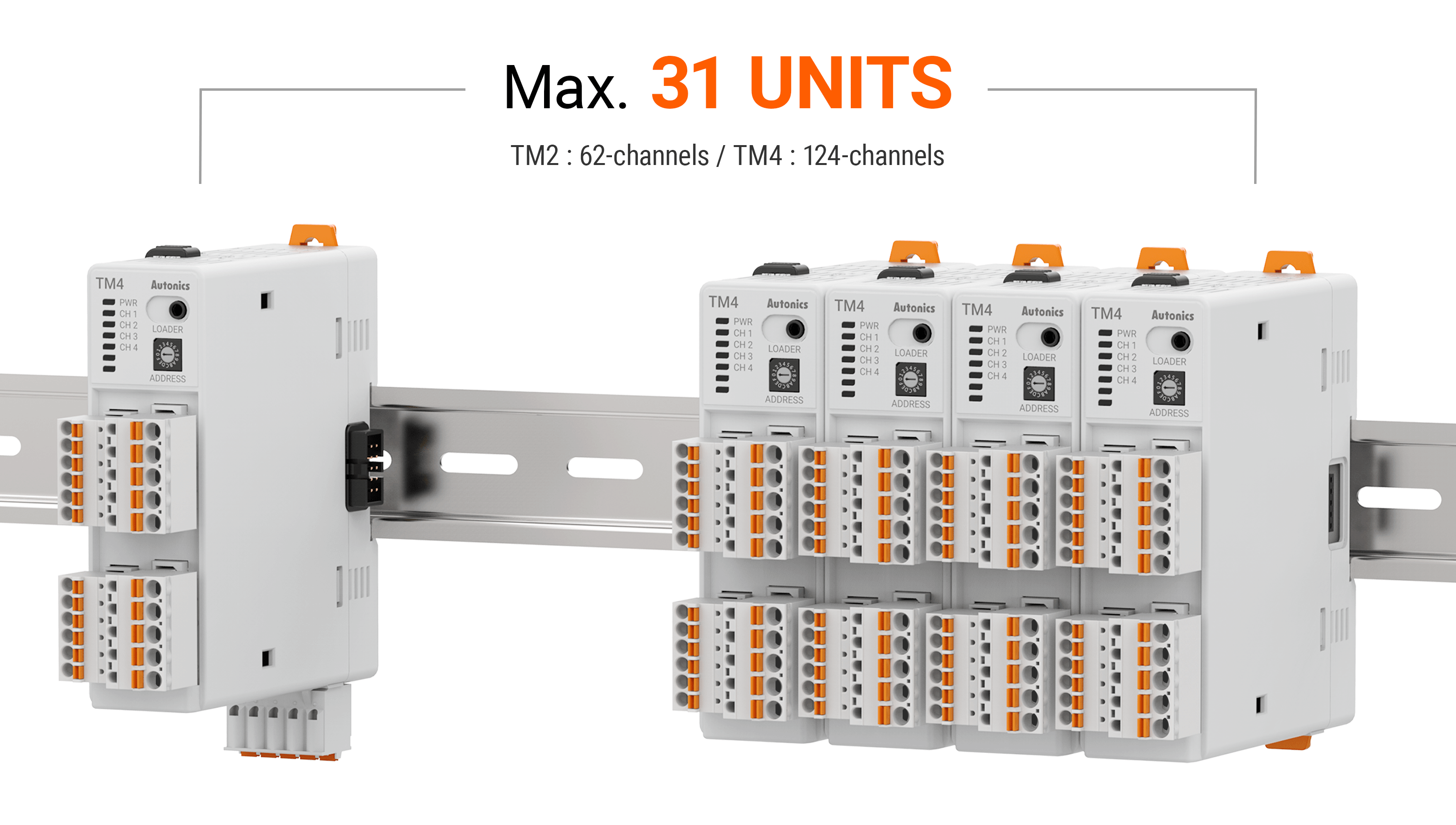

Modular Expansion Up to 31 Units

Up to 31 units can be connected with the side expansion connectors (124-channels/62-channels).

Individual power supply is not required, and communication is supported between modules.

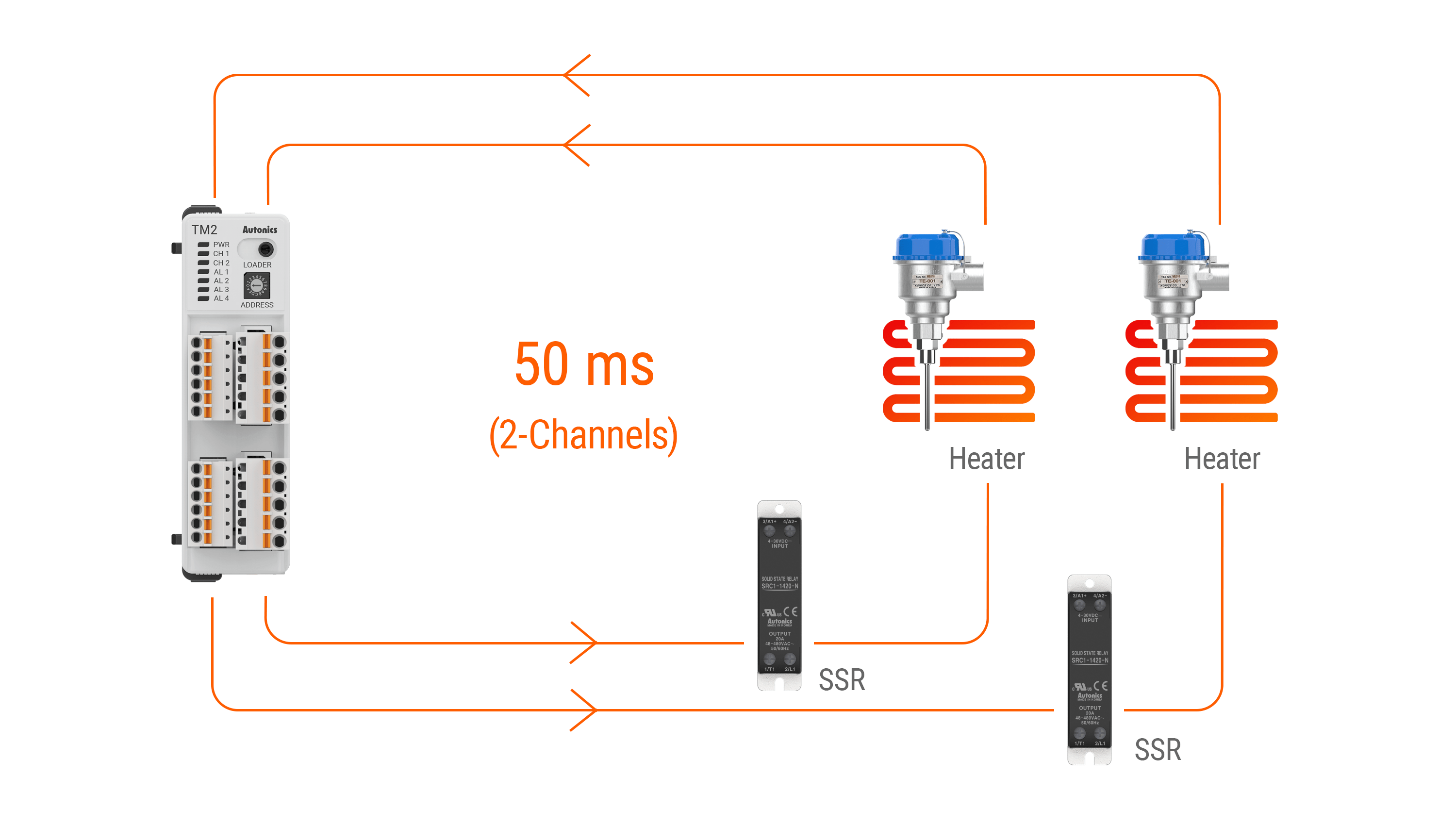

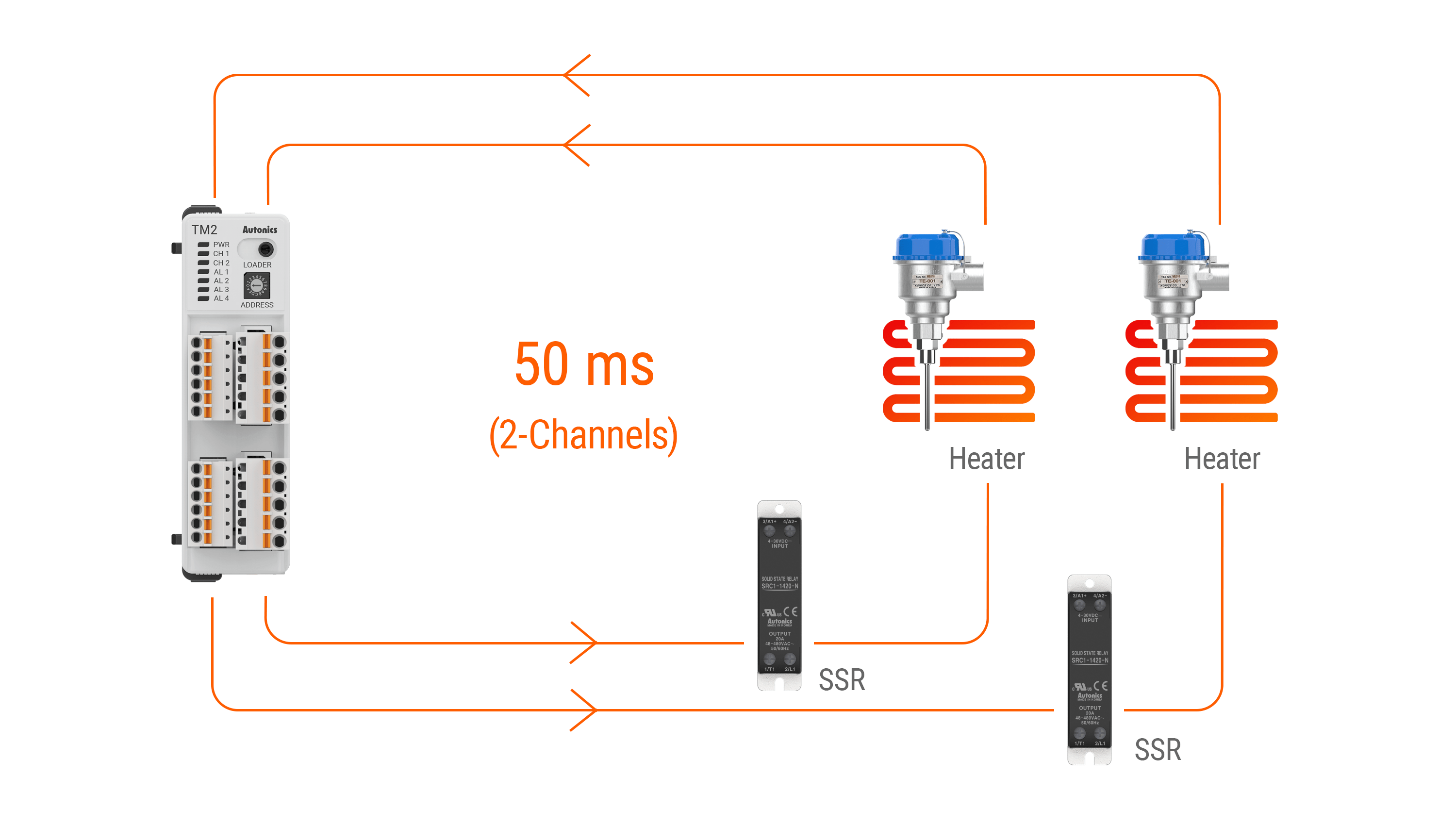

50ms High-Speed Sampling Rate

The TM2 models are capable of high-speed sampling rate of 50ms, providing ideal control in applications requiring high-speed response rates. (Simultaneous 2-channel control)

TM4 Series sampling speed : 100 ms

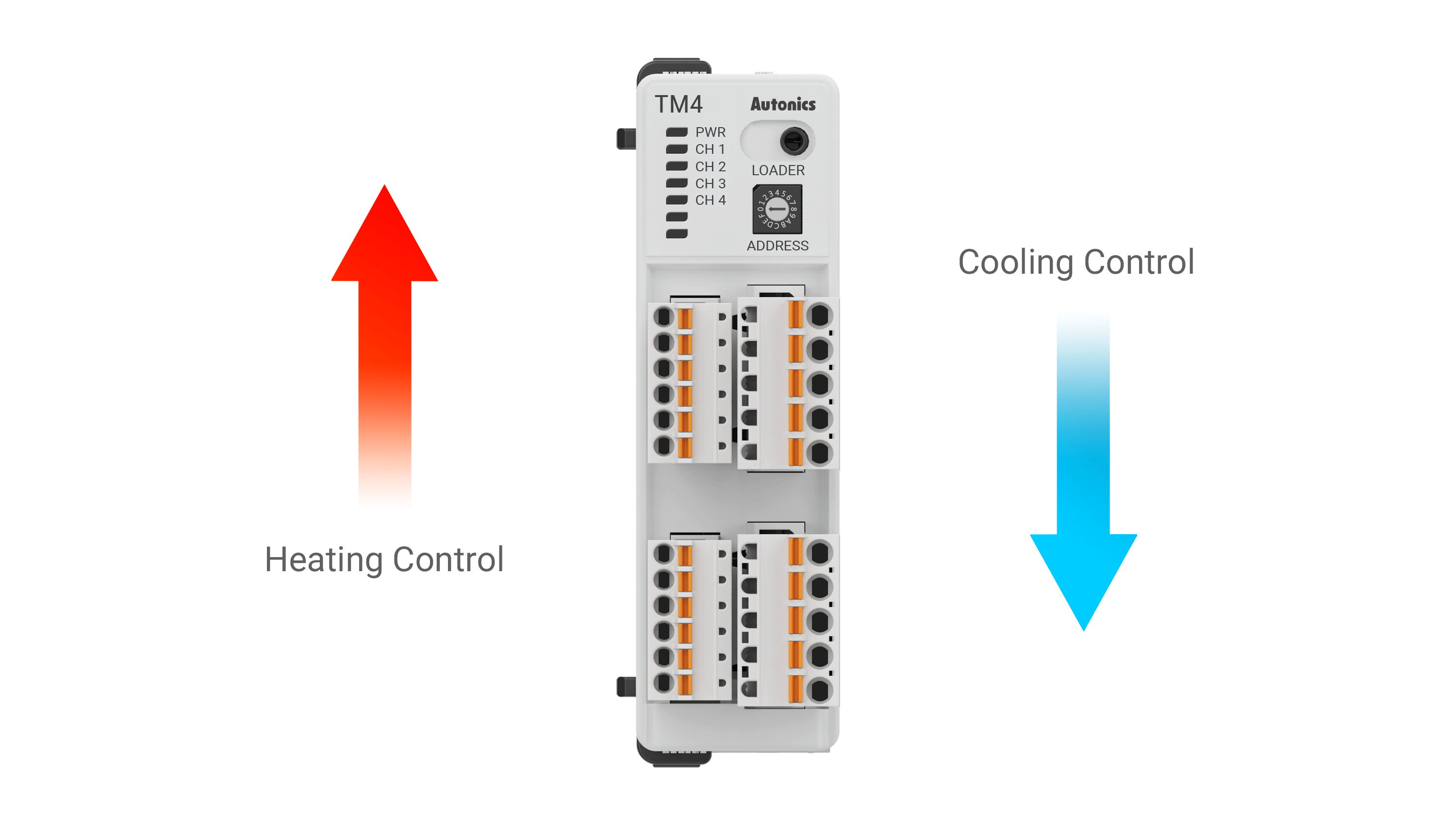

Simultaneous Heating & Cooling Control

The controllers can simultaneously control heating and cooling elements, providing efficient temperature control.

Switch Between Current Output and SSR Drive Output

Depending on the application, users can select between current output and SSR drive output by parameter configuration through DAQMaster. (TM2-□2C□ models)

Connector Wiring

Easy wiring and maintenance with various connectors : sensor input connectors, control output connectors, power/communication connectors

Power/communication connectors can only be connected to base units. (TM□-□□□B models)

Applications

-

Rubber Extrusion / Plastic Injection Molding Process

-

Potato chip manufacturing and packaging process

This is an application example of potato chip manufacturing and packaging process using Autonics products.

-

Chip Bag Filling, Sealing, and Cutting

Multi-channel modular temperature controllers and solid state relays with integrated heatsink are used for fast and stable temperature control during potato chip bag sealing process.