Description

- High resistance to impact and wear caused by contact with workpieces or wire brushes (sensor head/housing: stainless steel)

- Reduced risk of malfunction caused by aluminum chips

- 360° ring type operation indicator (red LED) (except M8 models)

- Oil resistant cable

- IP67 protection structure (IEC standard)

- PTFE coating prevents malfunctions caused by welding spatter (spatter-resistant models)

|

|

|

|

|

|

|

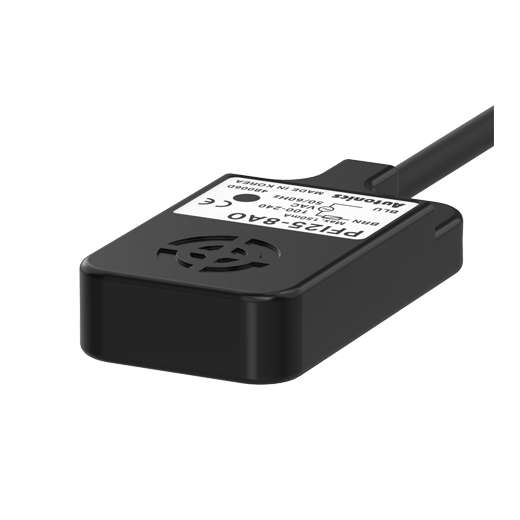

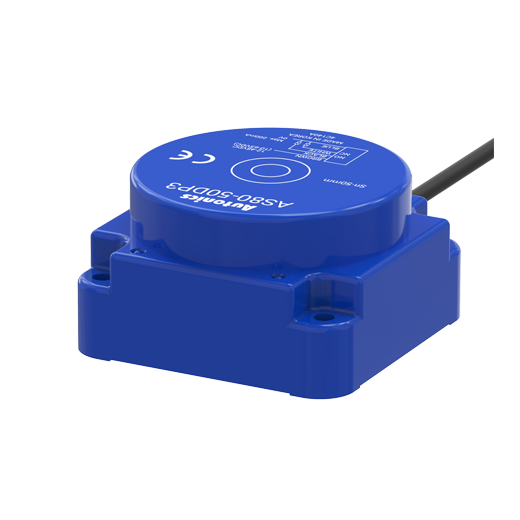

Available in Various Sizes and Cable Types

The sensors are available in M8, M12, M18, M30 size models, and cable/cable connector types allowing installation in tight or limited spaces and various other user settings.

Thick 0.8 mm Metal Sensor Heads Provide Resistance to Impact and Wear

The thick 0.8mm metal sensor heads provide strong resistance to impact and wear, making the sensors ideal in environments where the sensor heads can be damaged or worn due to workpieces or wire brushes.

*Except for ø8mm model.

Impact Resistance

|

|

|

Sensors can be used safely even in harsh operating conditions without risk of damage to the sensor heads.

Wear Resistance

|

|

|

Sensors can be used safely even with the wear on the sensor heads caused by continuous wire brush use.

Reduced Risk of Malfunction Caused by Aluminum Chips

The sensors are designed to minimize the risk of malfunction due to aluminum chips, offering high performance in environment with metal debris.

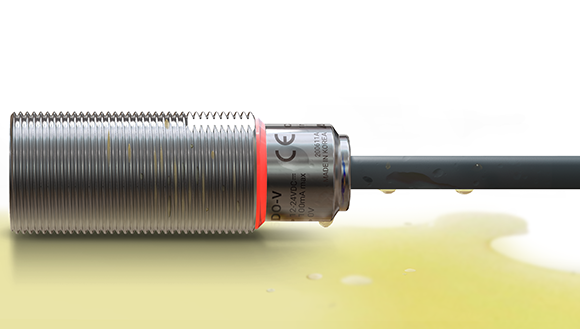

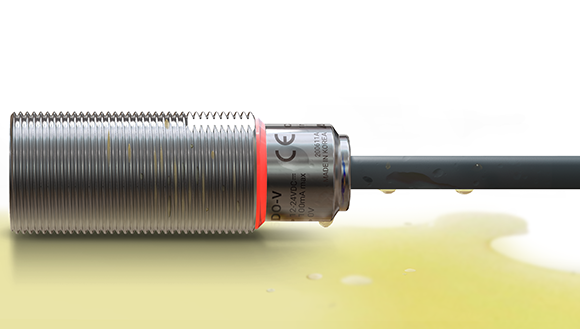

Oil-Resistant (PVC) Cable

The robust oil-resistant cable allows the sensors to be installed in environments with hydraulic fluids or cutting fluids.

Ring Type Operation Indicator (Red LED)

The 360˚ ring type operation indicator allows users to quickly identify operation status from various angles.

IP67 Protection Structure

The IP67 protection structure allows stable and error-free operation even in wet or dusty environments.

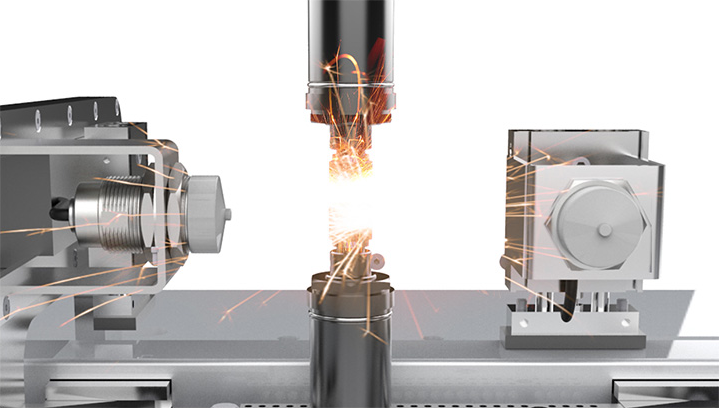

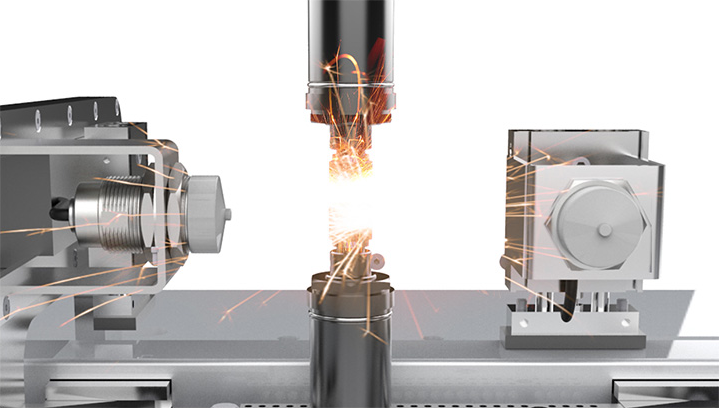

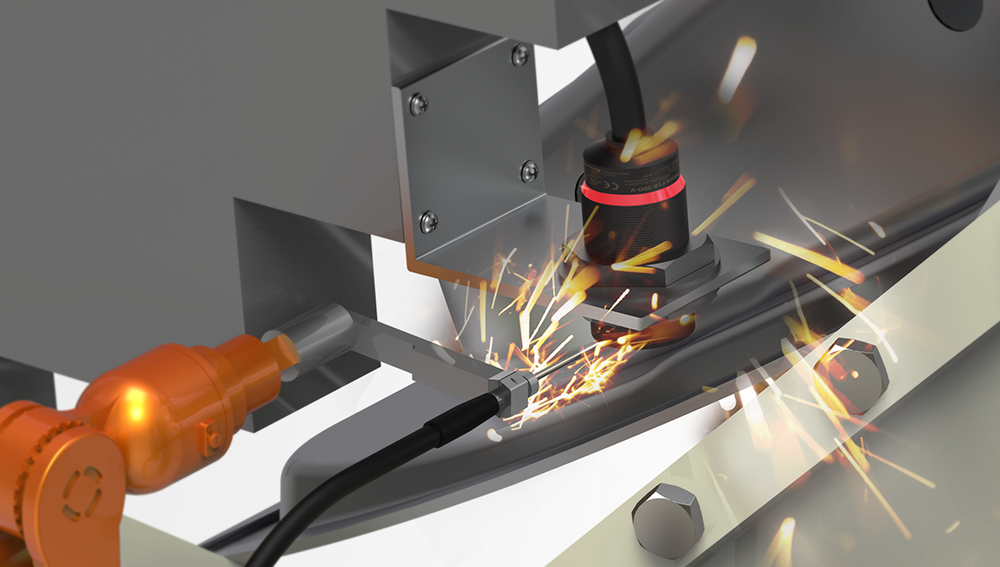

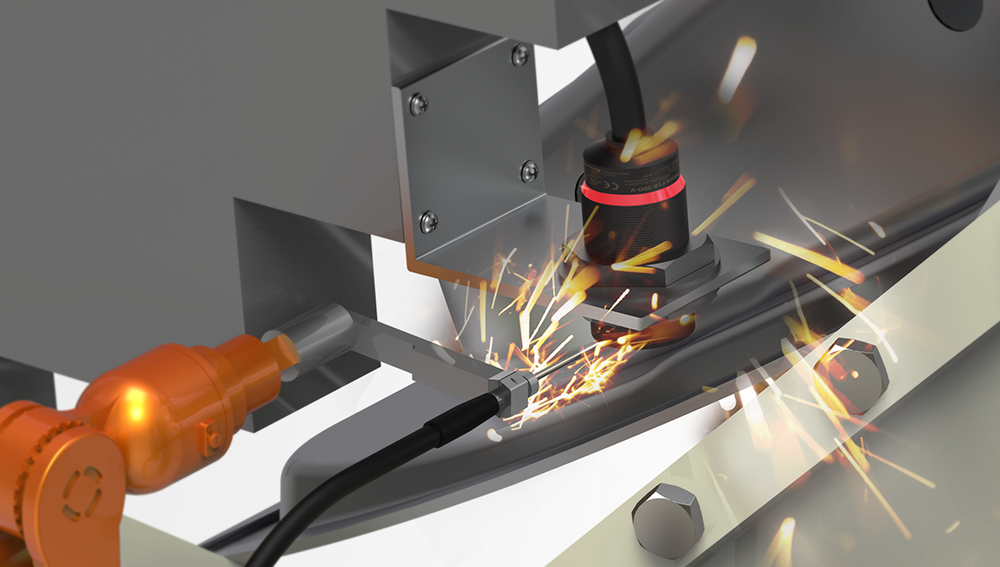

High Durability in Welding Environment

Full-metal inductive sensors feature high resistance to magnetic field noise from welding current and the non-stick PTFE coating prevents welding spatter from sticking on to the sensors which minimizes the risk of malfunctions during welding applications

*Spatter-Resistant PRFA□ Models

Applications

-

Meat Processing Conveyors

Full-metal inductive proximity sensors used to detect the location of food trays in meat processing lines.

-

Beverage Container Packaging Conveyors

Proximity sensors used to detect and count the quantity of bottles during beverage packaging process.

-

Parking Tower Entry/Exit

Inductive proximity sensors installed in parking turntables to detect the plates on the turntables and control the set/fixed position of the turntables.

-

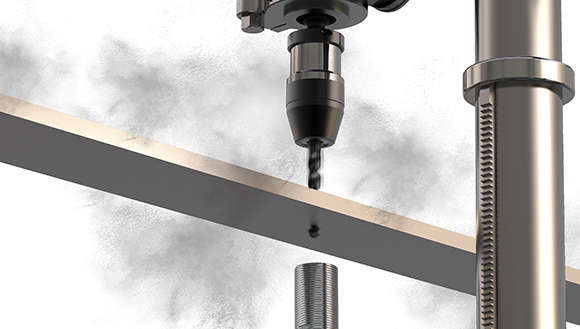

Automatic Drilling Machines

Proximity sensors are used as limit switches to check the precise location of parts in automatic drilling machines.